In recent years CNC (Computer Numerical Control) and 3D printing have become a common form

of manufacturing. Due to the high cost of commercial off-the-shelf CNC machines, manufacturers

have been building their own machines.

Creating an efficient and low cost tool chain, from planning stage to manufacture, will simplify the

process.

PROJECT GOAL

Create a simple tool chain for CNC (Computer Numerical Control) Manufacturing

The tool chain consists of four different tools:

- CAD (Computer Aided Design)

Software for planning the geometry and designing specific dimensions of any necessary component.

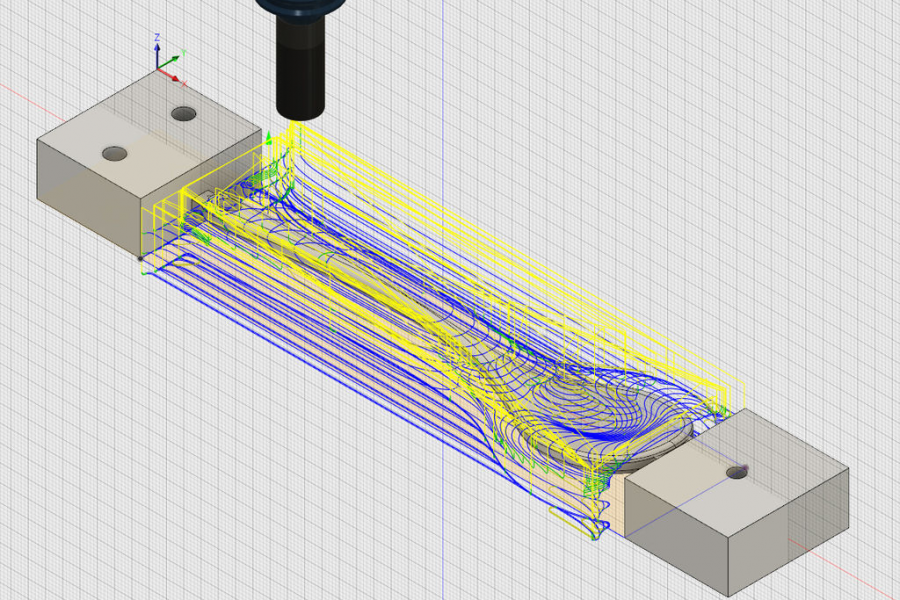

- CAM (Computer Aided Manufacturing)

Software that:

- receives CAD’s outcome.

- Creates tool paths (The path through space that the tip of a cutting tool follows on its way to producing the desired geometry of the workpiece) under user constraints and generates Gcode (machine language) files.

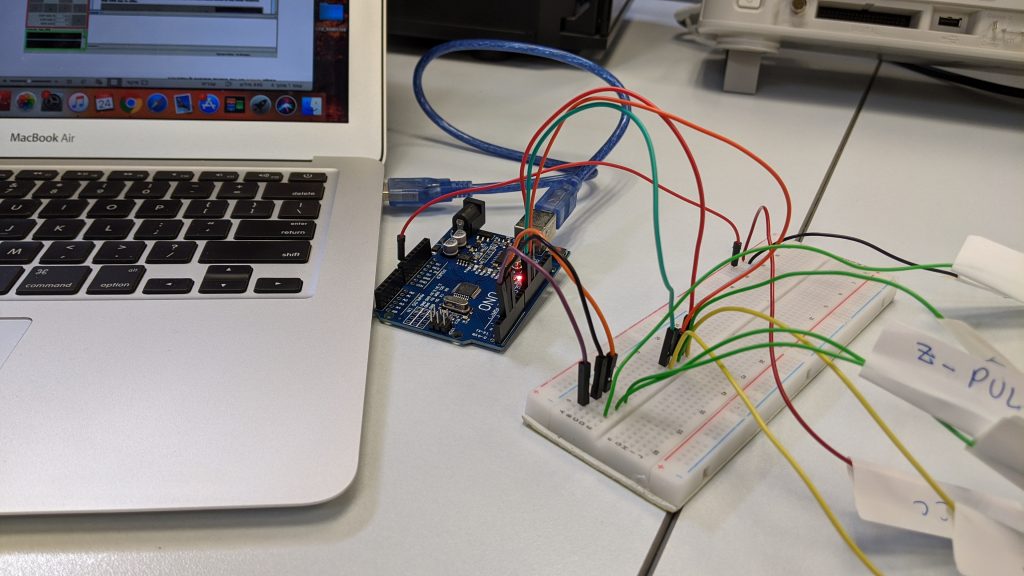

- Controller Interface

Software for interfacing with the hardware controller. The software is mainly for streaming the Gcode to the controller and for modifying and reading different control parameters.

- Controller

Hardware that controls motion of the cutting head according to the generated tool path.

The method was to test and evaluate existing independent tools and combine them into a single tool chain allowing easy CNC manufacturing.