Monitoring Air-Fuel ratio in car exhaust has key importance for engine maintenance.

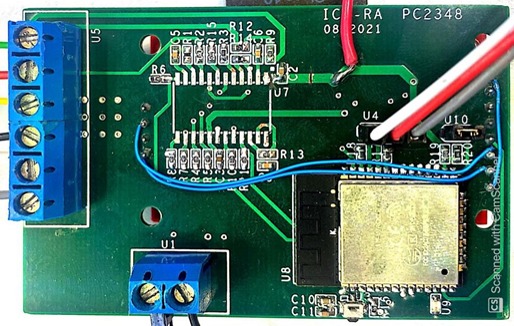

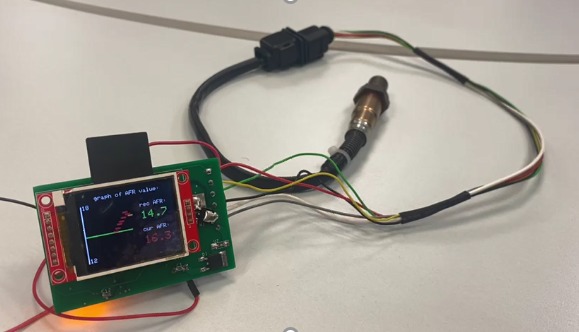

Implementing a customized micro-controller-based board for wide-band sensor, resulted with a small, low-cost solution delivering accurate AFR data to the driver.

Monitoring Air-Fuel ratio (AFR) has key importance for engine maintenance and efficiency.

In most cars there is a Narrow band sensor detecting if the AFR ratio in the car’s exhaust is richer than it should or leaner.

The project goal is to deliver a low-cost compact system to deliver more accurate and informative data on AFR status, that would be based on Wide-band sensor.

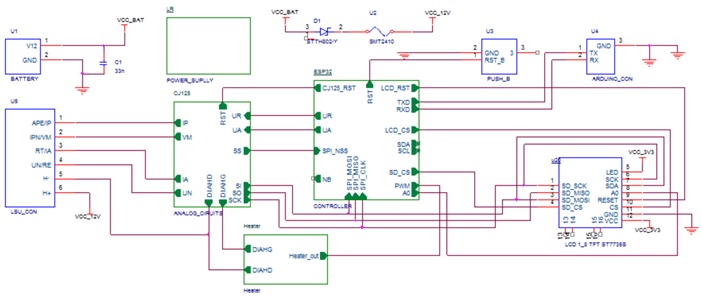

The “heart” of the board is ESP32 micro-controller supported with Arduino, it controls and supports all other components.

Other key components:

• LSU4.9 wide-band sensor- transform a difference between AFR in the exhaust and the outside air to current and voltage change.

• CJ125- component that implements all the analog circuits needed to receive and deliver the data from LSU sensor

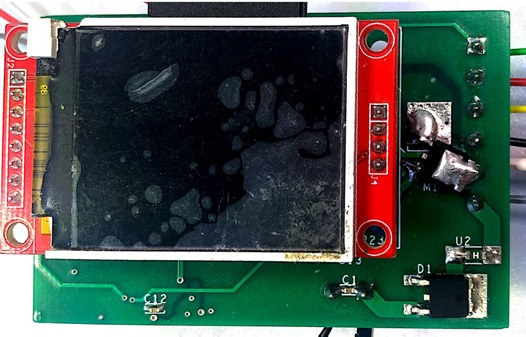

• LCD display and SD card- use to display the data received from the sensor and save it on the memory. communication is based on SPI protocol.

There are two main parallel processes starting when the engine is ignites:

• Sensor heat control- for the sensor to work properly, the system gradually heats the sensor to its operating temperature, and then monitors to keep it there.

• Data analysis- the system constantly reads voltage from the sensor, process and analyze it to get AFR value. Then the data is stored and displayed.

To support both processes, there is a complex software shell that implements the analysis, control, and graphic display.